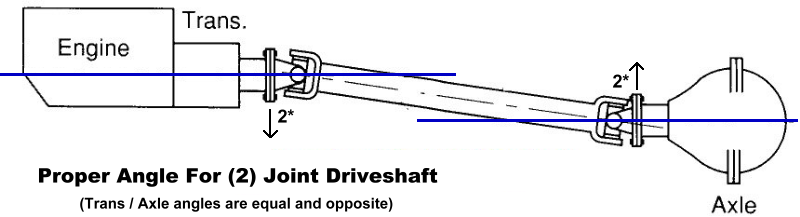

Hey now! What I said was... Move the front axle forward & tilt the drivetrain downward at the t-case. Especially if you are still determined to move the drivetrain backward with a doubler! Then maybe you would not have to cut as much of the firewall & tunnel & your u-joint angle would allow you to pivot the 14B pinion up at the same angle. ...ok, I did not Say ALL that, but it was inferred! Haha I for one appreciate the detailed explanation of what you are buying and why. Did you basically research each part of the steering system and write out your own explanation of how it works in a build thread form in order to keep track of it all? Or is this part of helicopter service work? Something tells me you have been writing this section of your build for quite some time! Pretty funny that I was also the guy that said, "So moving the family to Montana is the most important priority, right?" Haha NOPE! SHOP TIME! "It's winter", he says.

BTW... I never told you this but the last time I was at your apartment I noticed all those books in your book case... Mathematics, Metallurgy, Mechanics, etc... yet the one book I picked up was about Physics... imagine my surprise; hidden within it was a Hustler magazine! Haha BUSTED!

What 3D program are you using?

Sent from my "two hands on a keyboard"

Reply With Quote

Reply With Quote